A steel billet is a semi-finished metal product made from raw steel and used as a primary material in manufacturing and construction industries. It is typically cast into a solid, rectangular or square shape and produced through continuous casting or hot rolling processes.

Steel billets serve as the foundation for creating finished steel products such as bars, rods, wires, angles, and structural components. Known for their strength, durability, and versatility, steel billets are widely used in building infrastructure, automotive manufacturing, machinery production, and industrial fabrication. Their uniform composition and high quality make them essential in modern steel processing.

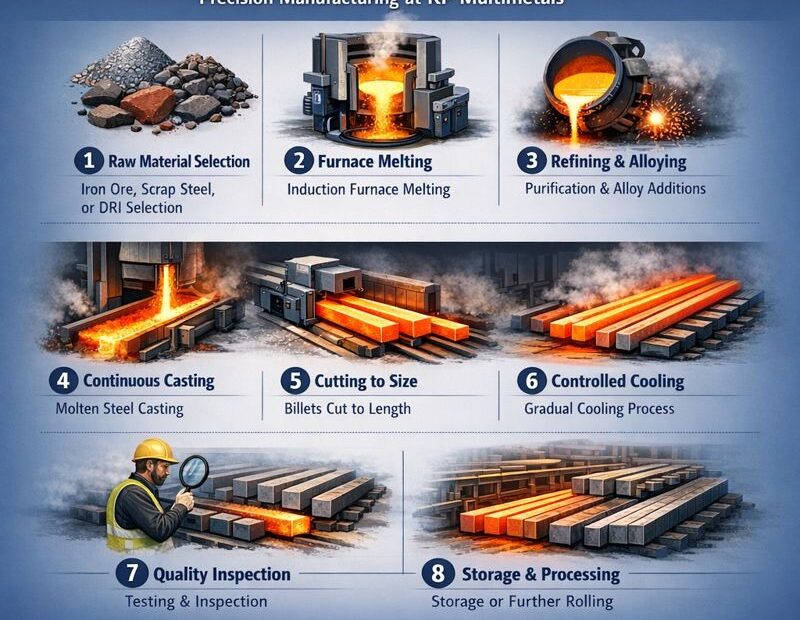

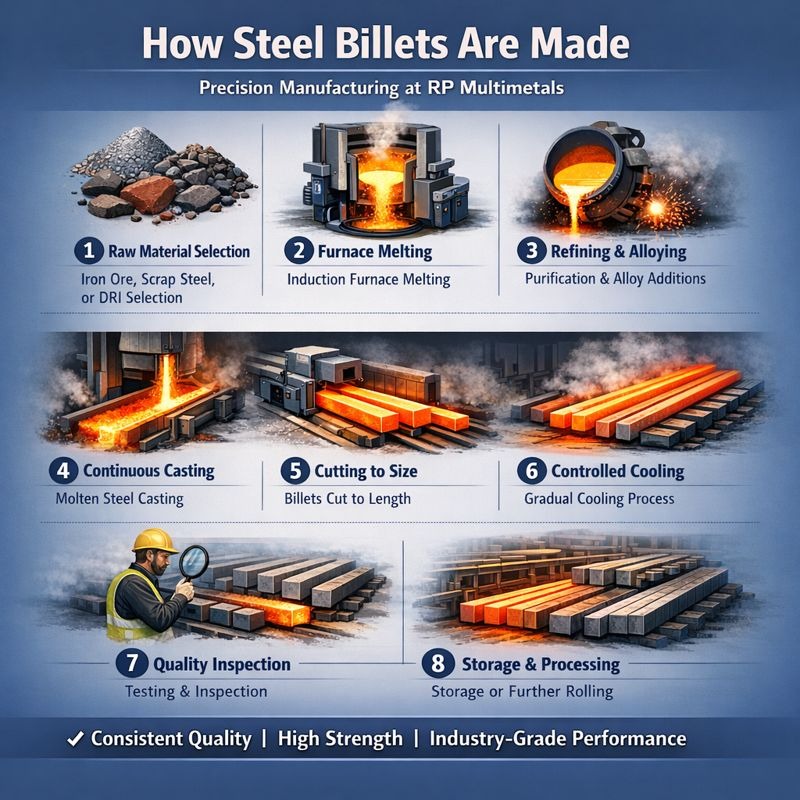

How are Steel Billets Made?

Steel billets are produced through a controlled, multi-stage manufacturing process at Rp multimetals to ensure strength, consistency, and quality. Below is a complete step-by-step explanation:

- Raw Material Selection

High-quality raw materials such as iron ore, scrap steel, or direct reduced iron (DRI) are carefully selected based on the required steel grade. - Melting in Furnace

The raw materials are melted in an induction furnace, where electromagnetic currents generate heat within the metal, allowing efficient and controlled melting to produce high-quality molten steel. - Refining and Chemical Adjustment

Impurities like sulfur and phosphorus are removed. Alloying elements (carbon, manganese, chromium, etc.) are added to achieve desired mechanical properties. - Continuous Casting

The refined molten steel is poured into a continuous casting machine, where it solidifies into long, uniform steel strands with square or rectangular cross-sections. - Cutting to Billet Lengths

The solidified strands are cut into standard billet lengths using automated cutting systems. - Cooling and Solidification

Billets are cooled under controlled conditions to prevent cracks and internal defects. - Surface Inspection and Quality Testing

Each billet undergoes visual inspection, dimensional checks, and non-destructive testing to ensure structural integrity and consistency. - Storage or Further Processing

Finished steel billets are either stored for sale or sent for further rolling into bars, rods, or other steel products.

This process ensures steel billets meet industry standards for strength, durability, and performance across construction and manufacturing applications.

Types of Steel Billets

Understanding the different types of steel billets helps buyers and engineers choose the right material for their specific applications. Below is a clear, value-driven explanation of each type:

1. Continuous Cast Billets

Continuous cast billets are produced directly from molten steel using a continuous casting process. This method ensures uniform chemical composition, better internal structure, and minimal defects. These billets offer consistent strength and are widely used in construction, reinforcement bars, and industrial manufacturing due to their cost efficiency and reliable quality.

2. Rolled Billets

Rolled billets are created by hot-rolling steel blooms or ingots into smaller cross-sections. This rolling process improves surface finish and mechanical strength. Rolled billets are commonly used where precise dimensions and enhanced durability are required, such as in automotive parts and heavy machinery components.

3. Square Billets

Square billets have equal width and height, making them easy to process into bars, rods, and wire products. Their balanced shape allows uniform stress distribution, making them ideal for structural applications, fasteners, and fabrication industries.

4. Rectangular Billets

Rectangular billets are wider than they are thick and are often used for producing flat bars, plates, and customized steel profiles. They are preferred when specific width requirements or flat rolling processes are involved, especially in infrastructure and industrial projects.

5. Special Alloy Billets

Special alloy billets are manufactured by adding elements such as chromium, nickel, molybdenum, or vanadium to enhance properties like corrosion resistance, heat tolerance, and tensile strength. These billets are essential in aerospace, oil & gas, power plants, and high-performance engineering applications where standard carbon steel is insufficient.

Each billet type serves a distinct purpose, and selecting the right one ensures better performance, cost efficiency, and long-term reliability in end-use applications.

Uses of Steel Billets

Steel billets are fundamental raw materials used across multiple industries due to their strength, adaptability, and ease of further processing. Below are the key applications explained clearly for practical understanding:

1. Construction Industry

Steel billets are extensively used in construction to manufacture reinforcement bars (TMT bars), beams, columns, and structural sections. Their high load-bearing capacity and durability make them essential for buildings, bridges, highways, and large infrastructure projects where safety and longevity are critical.

2. Automotive Sector

In the automotive industry, steel billets are transformed into components such as axles, shafts, gears, and fasteners. Their ability to be alloyed and heat-treated allows manufacturers to achieve precise strength, toughness, and wear resistance required for vehicle performance and safety.

3. Engineering and Machinery

Steel billets serve as the base material for producing machine parts, tools, and industrial equipment. They are widely used in heavy machinery, manufacturing plants, and mechanical systems due to their reliability, machinability, and ability to withstand high stress and continuous operation.

4. Wire Drawing

In wire drawing applications, steel billets are processed into wire rods and further drawn into fine wires. These wires are used in electrical cables, fencing, springs, fasteners, and mesh products. The consistent quality of billets ensures smooth drawing and uniform wire strength.

What Is the Difference Between Steel Billets and Steel Bars?

| Feature | Steel Billets | Steel Bars |

| Manufacturing Stage | Semi-finished product | Finished or near-finished product |

| Production Method | Continuous casting or initial rolling | Hot rolling or cold rolling of billets |

| Shape | Mainly square or rectangular | Round, square, flat, hexagonal, and more |

| Size & Dimensions | Larger cross-sections, less precise | Precise dimensions and standardized sizes |

| Surface Finish | Rougher surface | Smooth and refined surface |

| Purpose | Used as raw material for further processing | Ready for direct use or fabrication |

| Level of Processing | Minimal processing | Extensive processing |

| Customization | High flexibility for reshaping | Limited, already standardized |

| End-Use Applications | Used to produce bars, rods, wires, and profiles | Used in construction, machinery, and fabrication |

| Cost per Unit | Lower, as a base material | Higher, due to additional processing |